FT / BFT35-11 Series FRP axial fan

use :

FT35-11 FRP axial fan impellers, shells are made of glass fiber reinforced plastic composite material made of. Fans of the series has a simple structure, low noise, easy installation, good corrosion resistance, high static pressure and efficiency, smooth operation, mechanical vibration characteristics. Widely used in the pickling section, laboratories, basements, power plants, electroplating, oxidation plants and other sites containing corrosive gases. Also for general industrial and mining enterprises, warehouses, office buildings, homes and other places use ventilation. More can be applied to a longer interval pipeline installed in series to increase the pressure inside the tubes. The transport of gas must not contain viscous material, contained dust and hard particles ≤ 150mg / m3 , humidity should not exceed -20-6 0 ℃, relative Humidity ≤ 100% .

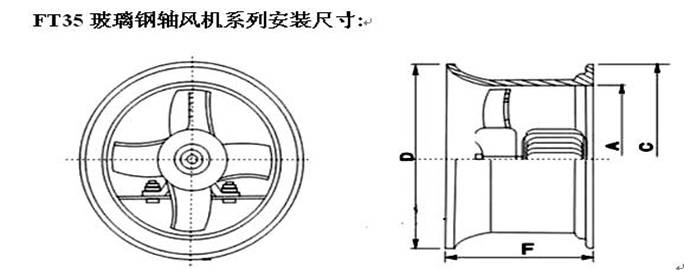

FRP axial fan structure and features :

This series fan mainly by the impeller, chassis, motor.

Impeller: made of fiberglass.

Chassis: the hairdryer, frame composition. FRP duct between the cylindrical impeller to maintain a certain gap, the stent is made by the sections and connected to the duct.

machine: FT35 fan equipped with the same power of the axial fan motor, BFT35 fans equipped with explosion-proof motor. Users can also be equipped with the same power required axial fan motor: YSF ( YBF ) series motor

FRP fan axial fan of the series of high aerodynamic efficiency, low noise, corrosion-proof and strong.

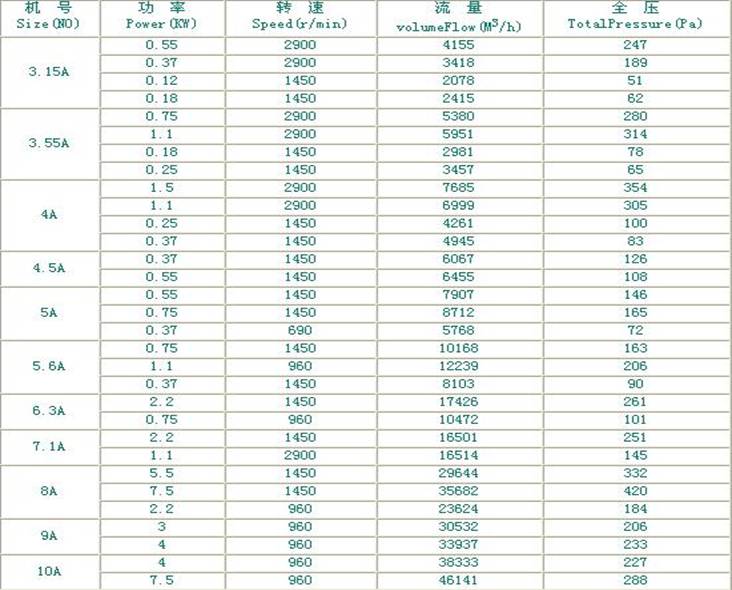

Performance parameters:

A . FRP axial turbine installation Precautions

1 , fans installation, you should first check the parts connections are secure, rotation is flexible, and to check whether the debris inside the casing.

2 , fans in combination with the base surface, when the import and export of duct connection, adjust natural fit, can not force the connection, never allow duct weight concentrated on the cabinet to avoid machine affect the normal operation of shell deformation. Importers fan duct hose connection application, and note the horizontal position of the fan.

3 , After installing attempted to call rotation of the impeller, check for a flexible, found inadequacies should be adjusted.

4 , installation, commissioning can be carried out properly after each part. Commissioning process to strictly control the current, can not exceed the rating. To prevent the motor due to over

Upload and burned, in fans startup and commissioning, it must be conducted under the no-load conditions. As well, the valve is opened gradually until a predetermined condition .

two. fan maintenance system

1 , FRP axial fan must hand use, personal service.

2 , fans are not allowed sick to run.

3 , periodically clear the dust inside the fan, especially on the impeller dust, dirt and other impurities, in order to prevent corrosion and imbalances.

4 , fan repairs must be emphasized first stop off.

5 , in addition to the lubricant should be replaced after each dismantling repair, but under normal circumstances, from March to June change the oil.

Guangzhou KEZHONG Ventilation Equipment Co., Ltd.

Zhaoqing Gaoyao Duzhen waist Kong community (over the sea longan Island) Six

Name: He Junhua Phone: 13580316132 Fax: 0758-8520036

Specializing in well-ventilated areas to concentrate on, let families all for you to create a fresh environment!

FRP axial fan, glass steel mixed flow fan, mist purification tower, FRP centrifugal fan, anti-corrosion plastic fan

Powered by Guangzhou KEZHONG Ventilation Equipment Co., Ltd. ©2008-2015